Lockers

Lockers

ecos lockers are modular and intelligent

modular

In one installation you can manage and secure all your items, no matter the size. We offer unlimited configurability, letting you decide per compartment and not just per column.

intelligent

You have a wide range of functions to choose from, with the help of which your processes are automated. 3 functions can also be combined in one tray.

modular

Because in one installation you can manage and secure all your items, no matter the size. Because we offer unlimited configurability, letting you decide per compartment and not just per column.

intelligent

Because you have a wide range of functions to choose from, with the help of which your processes are automated. Because 3 functions can also be combined in one tray.

Locker types

Locker compartments

38

different sizes

0,5 to 350 L

content

1g to 200kg

weight recognition

Drawer compartments

Locker types

38

different sizes

0,5 to 350 L

content

1g to 200kg

weight recognition

Locker compartments

Drawer compartments

Functions

The multitude of detections offered makes your locker system intelligent. As standard, a multi-coloured LED visualises the status of the managed object at a glance.

Recognition

ID

There is a key slot in the locker or drawer, therefore objects can be managed together with a bunch of keys. The plug can also be used in an airlock application.

RFID

The most proven method to confirm the presence of objects in the compartments. First, the objects must be recognisable by attaching RFID stickers. These come in different sizes, shapes and specifications so that every possible object with a metal or plastic surface is reliably detected. Weapons as well as tools and radios are recognised and the coloured LED informs whether the right object, the wrong object or no object is in the compartment.

Multi RFID

For several objects that are to be managed logically together, we offer multiple RFID detection. Here, up to 4 objects can be recognised with 99.99% certainty. The objects can simply be inserted without having to pay attention to markings. Additional objects are possible in principle, but this reduces the accuracy and user-friendliness, which is why we limit the number for precautionary reasons. The LED display will only turn green when all the stored objects have been recognised.

Functions

The multitude of detections offered makes your locker system intelligent. As standard, a multi-coloured LED visualises the status of the managed object at a glance.

Recognition

ID

There is a key slot in the locker or drawer, therefore objects can be managed together with a bunch of keys. The plug can also be used in an airlock application.

RFID

The most proven method to confirm the presence of objects in the compartments. First, the objects must be recognisable by attaching RFID stickers. These come in different sizes, shapes and specifications so that every possible object with a metal or plastic surface is reliably detected. Weapons as well as tools and radios are recognised and the coloured LED informs whether the right object, the wrong object or no object is in the compartment.

Multi RFID

For several objects that are to be managed logically together, we offer multiple RFID detection. Here, up to 4 objects can be recognised with 99.99% certainty. The objects can simply be inserted without having to pay attention to markings. Additional objects are possible in principle, but this reduces the accuracy and user-friendliness, which is why we limit the number for precautionary reasons. The LED display will only turn green when all the stored objects have been recognised.

Charging

To always be ready for work, it is crucial to have charged the required tools at hand. So that you no longer have to worry, our smart compartments combine the securing and charging of your cordless screwdrivers, laptops, smartphones or radios. In addition, the charge level of the objects can also be measured and displayed. This allows you to keep an overview at all times and detect defective equipment promptly. The LED pulses when charging and indicates when the equipment is fully charged. Depending on the setting in the ecos webman, only charged equipment is released.

5V

12V

230V

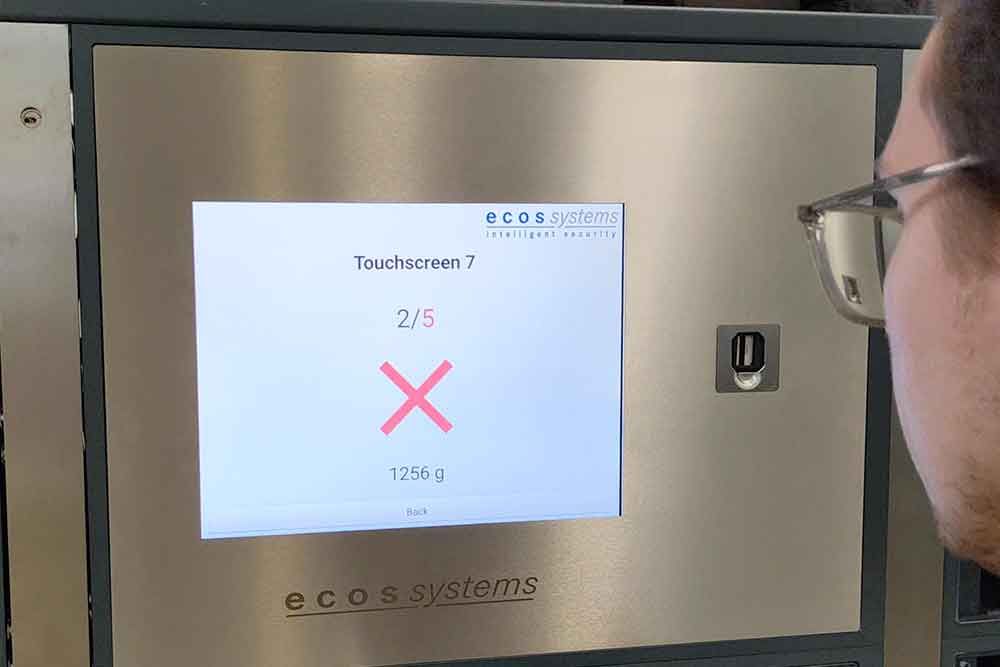

Weighing

The most accurate method allows the detection of objects weighing from 1g to 100kg. Due to a tolerance of less than 1%, the object can be identified with certainty. This function is particularly useful when determining the inventory of similar objects such as ammunition or spare parts. The number can be detected automatically and, in the event of a discrepancy, a reason can be entered via the operating terminal. In addition, a notification is sent and the LED lights up red.

Combination

RFID + Weighting

You can combine several functions in one compartment without any problems. The most common combinations are RFID recognition and loading function as well as weight and RFID recognition. Optional foam forms can better organize the different objects in the locker.

RFID + Charging

Opening types

Reinforced door

The most stable version has 2 high-quality hinges that can withstand 50,000 openings without any problems. Each compartment has a 2,5 mm thick stainless steel front with gaps of less than 1 mm. This is a condition to get acknowledged for use in the German Military. Here you have a wide choice of heights and widths. The depth is either 25 cm or 50 cm.

Transparent door

For more non-safety-critical applications or the preference to see all objects at a glance, polycarbonate doors can be installed instead of stainless steel fronts. This can be done on a compartment basis.

Motorised

Drawers are the most secure type of locker as they prevent the biggest security gap in a locker system: If an employee forgets to close the door, the objects stored inside remain freely accessible, regardless of the steel thickness and penetration resistance of the system. The automatically closing drawers eliminate this risk and ensure the security of your objects at all times. You can determine the waiting time in the ecos webman.

With 2 redundant and high-quality gears, the stability of the drawer is ensured for the entire life of the system. In addition, the drawer detects resistance such as fingers or incorrectly inserted objects so that it stops automatically when moving out and in.

The 1m/4 drawer offers an ideal size for storing smartphones. Tablets or weapons, on the other hand, are best stored in the 1m/2 drawer. Both options have a depth of 25 cm. All other drawers are 50 cm deep and 45 cm high per block, but differ in width. The L-drawers, for example, are ideal for managing laptops. Some options such as 230V charging are not possible due to the moving parts.

Deployable at any place

-

The standing locker system is the most commonly used type of system and is generally fixed to the floor and to the wall. Optionally, it can also be fixed to only one of the two. The standing locker system is particularly useful for a large number of objects to be managed and large objects that require 500 mm deep lockers. For ergonomic reasons, the system has a maximum height of 1.85m. Its bottom row can be configured as unused blind compartments.

-

For a small number of objects, the wall system is the most compact system form. Especially in combination with a key cabinet for managing small objects such as driver’s logbooks or smartphones, the wall system is ideal. For stability reasons, the maximum depth here is 250mm.

-

Our deep lockers can also become mobile systems via heavy-duty wheels. This is particularly useful when certain objects need to accompany the user. For stability reasons, we recommend a maximum of 3 block heights here, which corresponds to 1.4 m.

Do you have questions or need a quote?

"*" indicates required fields